How We Support

Schools

Automated Reporting

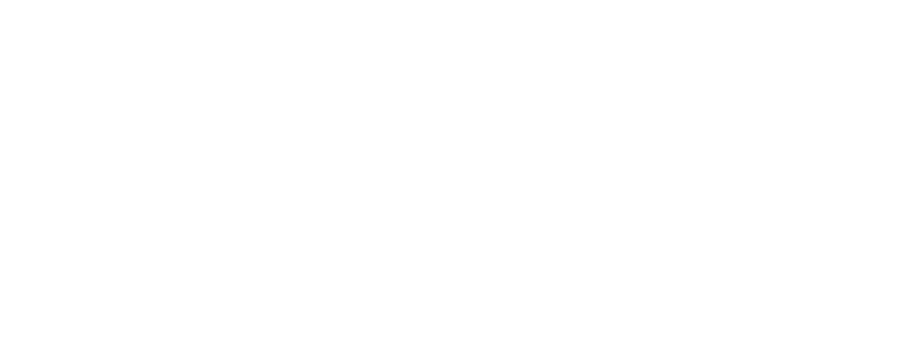

Save your staff time on their days off with automated temperature documentation accessible through fully auditable reports and easy to understand dashboards.

Prevent Food Losses

With always-on alerting – your staff will be notified anytime your equipment is trending outside of its normal range so you can take quick action and prevent food losses.

Energy Savings

Our sensors also allow us to not only provide monitoring and alerting – but also provide a more reliable gauge for internal temperatures resulting in significant energy savings.

Automated reporting and Compliance

Saved Time + Peace of Mind

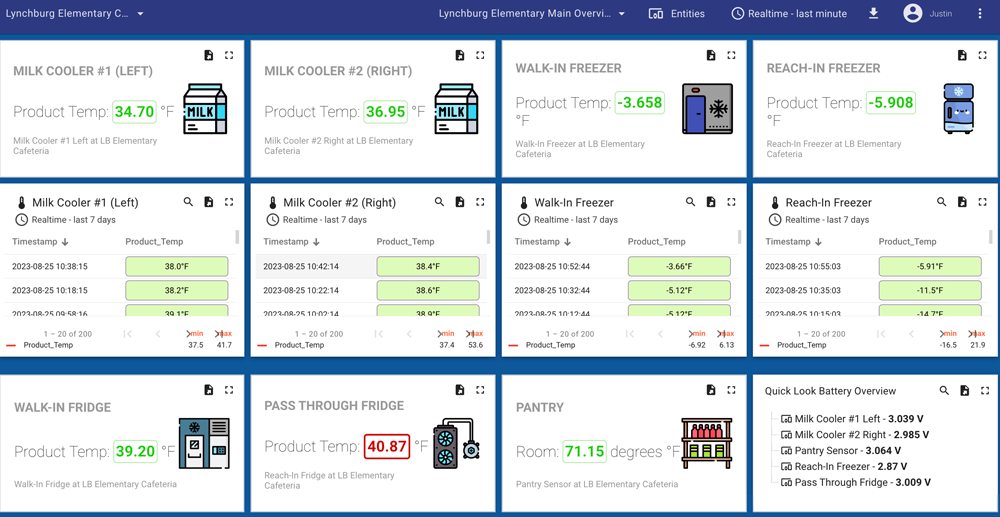

Schools and Universities across the country are required to maintain logs of the temperatures of the walk-in freezers and coolers in their cafeterias to keep their students and food inventory safe. These efforts take time and require food service staff to return to the school to check on these systems, even on weekends and holidays.

Onformant is able to fully automate this process and provide always-on reporting and alerting to notify your staff any time these systems move out of their typical temperature range – giving you time to correct the issues before any food inventory is lost. The system maintains a fully auditable historical database of one years worth of data with additional storage available to give you the data you need to stay in compliance with regulations.

Automated reporting and Compliance

Reduce Energy Use

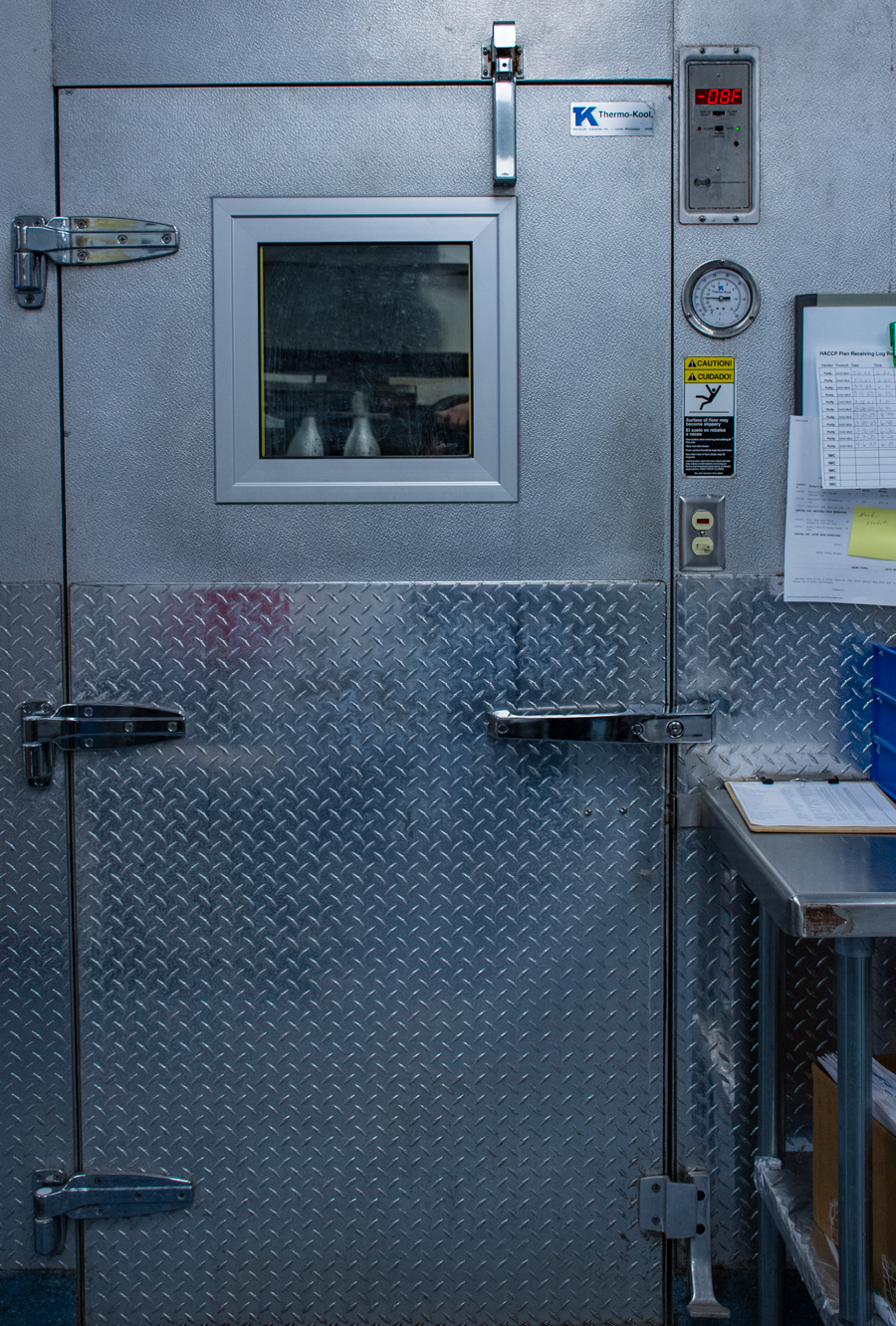

The same systems that we use to provide detailed reporting on the status of your food storage equipment don’t stop their contributions to your school with keeping you in compliance. Our sensors are designed to not just monitor – but also regulate the temperatures within the refrigerated space by mimicking the characteristics of stored food rather than the air around it. This change in temperature source maintains the quality of the food while reducing the overall frequency of compressor starts and stops which ultimately cuts down on the energy costs associated with the equipment.

This reduction in compressor firings also has an impact on the actual life of the equipment. By reducing the number of times the compressor starts and stops, the system reduces wear and tear which leads to fewer repairs and replacements, and saves the school money in the long run.

What are you waiting for?